Diverse Industrial Applications of Plastic Injection Molding

Table of Contents

Expanding the Reach of Plastic Injection Molding Across Industries #

Plastic injection molding is a versatile manufacturing process that supports a broad spectrum of industries and product requirements. The following key application areas highlight the adaptability and impact of this technology:

LED Automotive Lighting

LED Automotive Lighting

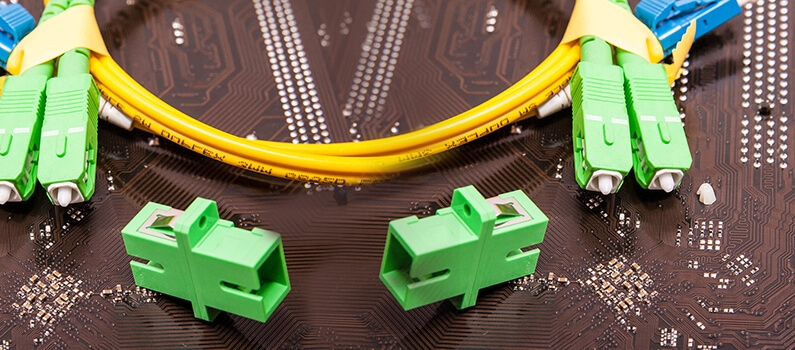

Fiber Optic Connectors

Fiber Optic Connectors

LED Display Panels

LED Display Panels

Projectors

Projectors

Medical Devices

Medical Devices

Other Injection Products

Other Injection Products

Assembly OEM

Assembly OEM

Key Application Areas #

- LED Automotive Lighting: Precision-molded components for modern vehicle lighting systems, enhancing both performance and design.

- Fiber Optic Connectors: High-accuracy plastic parts essential for reliable data transmission in telecommunications and networking.

- LED Display Panels: Custom-molded housings and structural elements for vibrant and durable display solutions.

- Projectors: Complex molded parts supporting the assembly and functionality of projection equipment.

- Medical Devices: Critical components produced with stringent quality standards for use in healthcare and diagnostics.

- Other Injection Products: A wide array of custom-molded plastic items tailored to unique client requirements across various sectors.

- Assembly OEM: Comprehensive OEM assembly services, integrating molded parts into finished products for diverse applications.

Plastic injection molding continues to drive innovation and efficiency across these industries, offering reliable solutions for both standard and highly specialized product needs.

There are no articles to list here yet.