Advancing Mold Development and Design for Precision Manufacturing #

Mold development and design are fundamental to achieving high-quality results in plastic injection molding. Our approach combines technical expertise, innovative processes, and advanced equipment to deliver reliable and efficient mold solutions tailored to diverse industry needs.

Overview of Mold Development #

The mold development process is a critical phase in plastic injection molding, determining the accuracy, durability, and efficiency of the final product. By leveraging extensive experience and a deep understanding of material properties, we ensure that each mold is meticulously designed to meet specific project requirements. Our team focuses on optimizing mold structure, enhancing production efficiency, and minimizing lead times.

Learn more about our mold development process

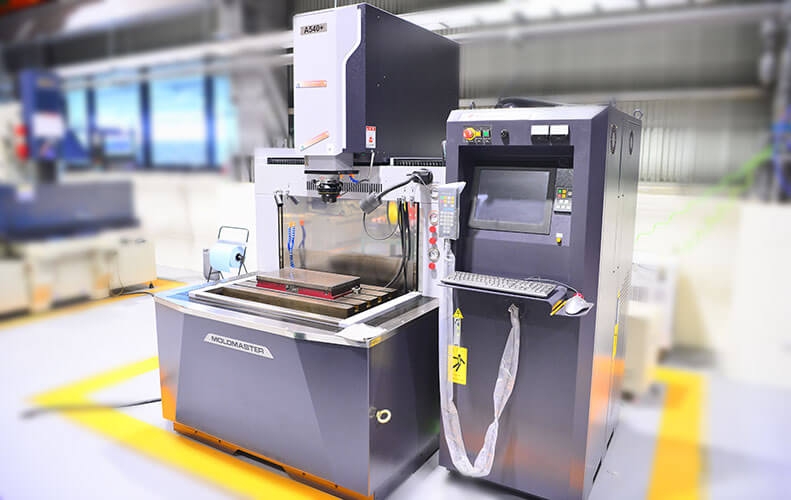

Equipment Introduction #

State-of-the-art equipment plays a vital role in the mold development process. We utilize advanced machinery and tools to support every stage of mold fabrication, from initial design to final production. Our investment in cutting-edge technology ensures precision, consistency, and the ability to handle complex geometries and high-volume demands.

Discover our equipment for mold development

塑膠射出模具設計開發公司

塑膠射出模具設計開發公司 塑膠射出模具設備

塑膠射出模具設備