Versatility of Plastic Injection Molding in Modern Manufacturing #

Plastic injection molding is a cornerstone technology in modern manufacturing, enabling the production of complex and high-precision components across various industries. Below is an overview of key application areas where this process demonstrates its value and adaptability.

Key Application Industries and Product Scopes #

LED Automotive Lighting

LED Automotive Lighting

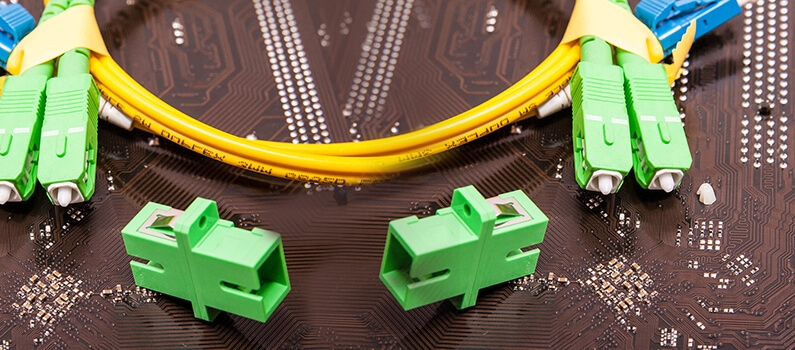

Fiber Optic Connectors

Fiber Optic Connectors

LED Display Panels

LED Display Panels

Projectors

Projectors

Medical Devices

Medical Devices

Other Injection Products

Other Injection Products

Assembly OEM

Assembly OEM

Application Highlights #

- LED Automotive Lighting: Precision-molded components for automotive lighting systems, ensuring durability and high performance.

- Fiber Optic Connectors: High-accuracy plastic parts for reliable fiber optic connections in telecommunications and data transmission.

- LED Display Panels: Components for large-scale and high-resolution LED screens, supporting various display applications.

- Projectors: Custom-molded parts for projector assemblies, contributing to optical performance and device reliability.

- Medical Devices: Specialized plastic components meeting stringent quality and safety standards for use in medical equipment.

- Other Injection Products: A broad range of custom-molded plastic items tailored to diverse industrial needs.

- Assembly OEM: Complete assembly solutions for original equipment manufacturers, integrating molded parts into finished products.

Plastic injection molding continues to be an essential process for delivering innovative and high-quality solutions across these sectors, supporting both standard and custom manufacturing requirements.