Comprehensive Guide to the Mold Development Process #

Mold development is a critical phase in plastic injection molding, often representing the highest cost in product creation. At Chia Kuan, we approach mold development through a structured, step-by-step process to ensure the final product meets both functional and aesthetic requirements while optimizing for manufacturability and cost-efficiency.

1. Requirement Assessment #

The journey begins with a thorough evaluation of your product’s needs. We analyze both the functionality and appearance of your design, recommending the most suitable materials and mold processes. This stage includes Design for Manufacturability (DFM), sample modeling, and defining product precision requirements to lay a solid foundation for the project.

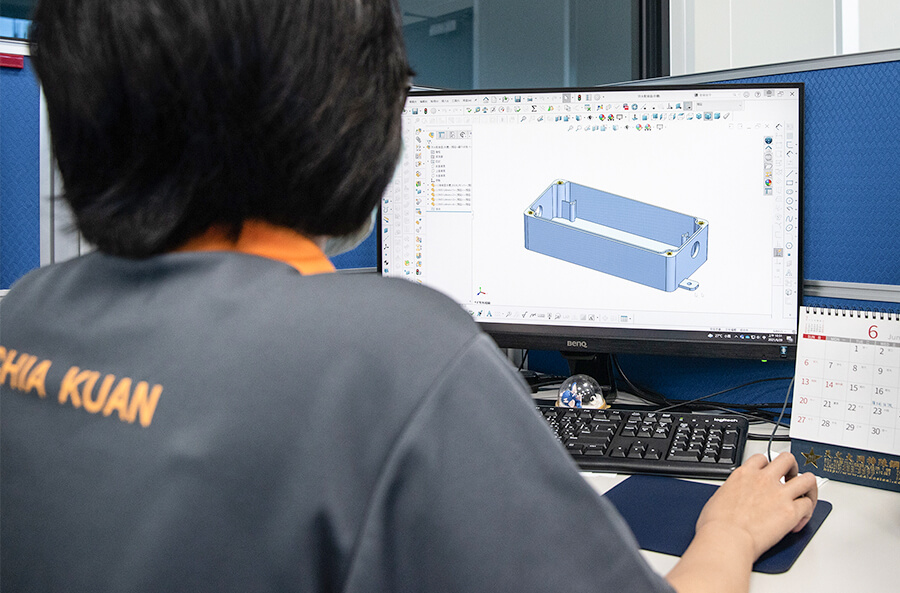

2. 3D Design #

Leveraging customer drawings or physical samples, our team utilizes advanced professional software such as Dassault Systèmes SOLIDWORKS Standard & Plastics Professional and Autodesk Product Design & Manufacturing Collection. This enables us to offer diversified mold manufacturing services, ensuring that every detail aligns with your specifications.

3. Production Planning #

We develop a tailored production schedule to meet your expectations regarding delivery time and order quantity. This careful planning ensures that timelines are realistic and resources are allocated efficiently, minimizing delays and maximizing productivity.

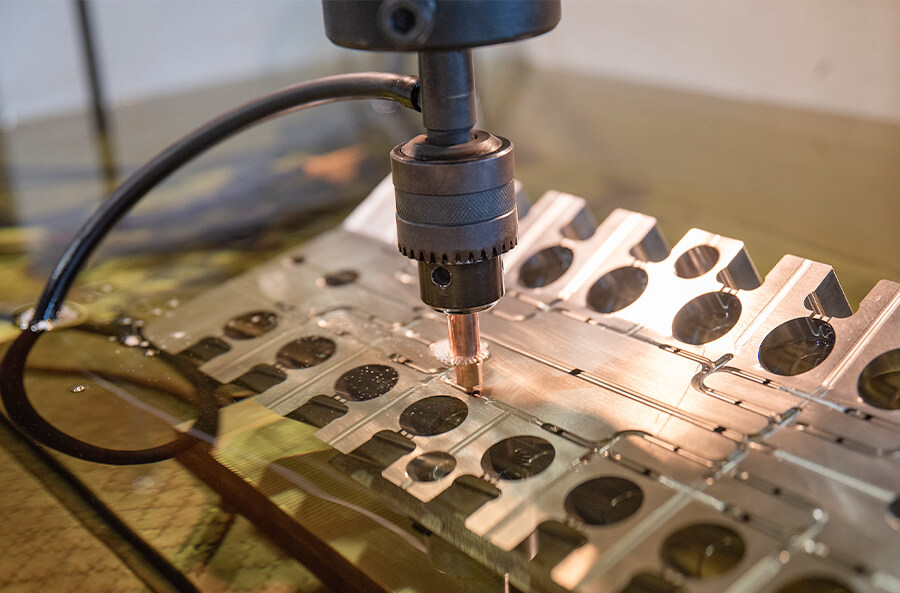

4. Mold Manufacturing #

With over 36 years of experience, Chia Kuan streamlines the mold manufacturing process. Our expertise allows us to reduce the number of trial runs, shorten development cycles, and lower manufacturing costs. The result is a mold that is ready for real-world application and mass production.

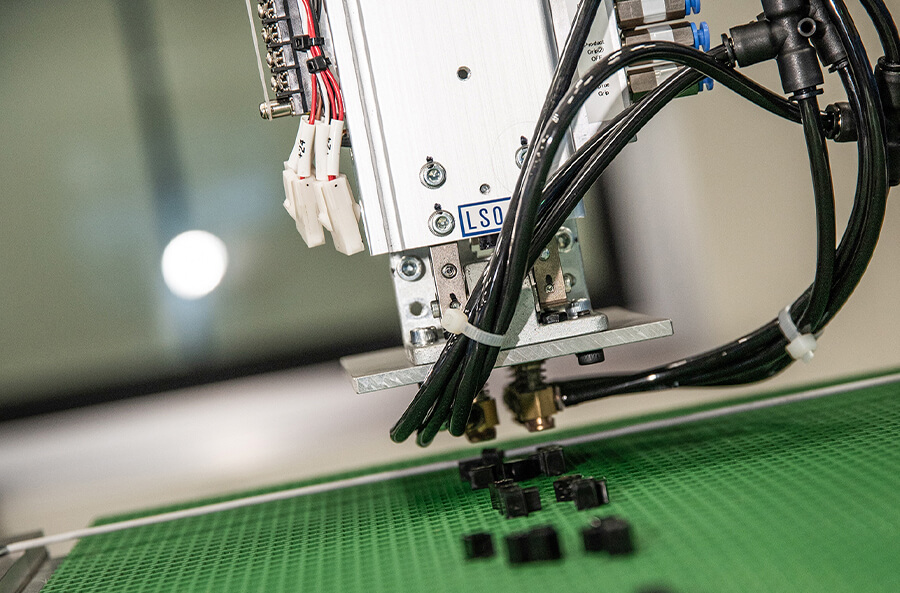

5. Quality Control #

Precision is at the core of our quality assurance process. Every production sample undergoes rigorous inspection to ensure it meets our high standards. This commitment to quality guarantees reliable results during mass production.

6. Production & Delivery #

Once the client approves the sample, we proceed to mass production, maintaining consistent quality throughout the process. The final products are delivered according to the agreed timeline, ensuring your project stays on track.

Visual Overview of the Mold Development Process #

This systematic approach ensures that every stage of mold development is handled with expertise, resulting in high-quality, reliable products ready for market.

Requirement Evaluation

Requirement Evaluation 3D Design

3D Design Production Planning

Production Planning Mold Manufacturing

Mold Manufacturing Quality Inspection

Quality Inspection Delivery

Delivery