Key Principles and Process of Plastic Injection Molding #

Plastic materials have become integral to contemporary living, with approximately 60% of daily necessities made from plastic. Among the various manufacturing methods, plastic injection molding stands out as a fundamental industrial technique, playing a pivotal role in the production of countless plastic products.

Plastic injection molding is recognized for its speed and efficiency. However, the inherent properties of plastic—particularly cooling and shrinkage—demand precise control over dimensions and appearance. Achieving this level of accuracy relies heavily on the technical proficiency and experience of both product designers and manufacturers.

With over three decades of industry experience, Chia Kuan leverages advanced software and hardware systems to deliver integrated, one-stop services. These services encompass every stage, from mold design and fabrication, through injection molding and quality management, to packaging and delivery. The commitment is to collaborate closely with clients, ensuring the production of high-quality plastic products and establishing trust as a reliable plastic injection molding OEM factory.

Core Elements of Plastic Injection Molding #

Three primary components define the injection molding process:

- Plastic Raw Materials

- Plastic Molds

- Plastic Injection Machines

Each of these elements can be further categorized according to specific manufacturing requirements.

The Injection Molding Cycle: Five Essential Steps #

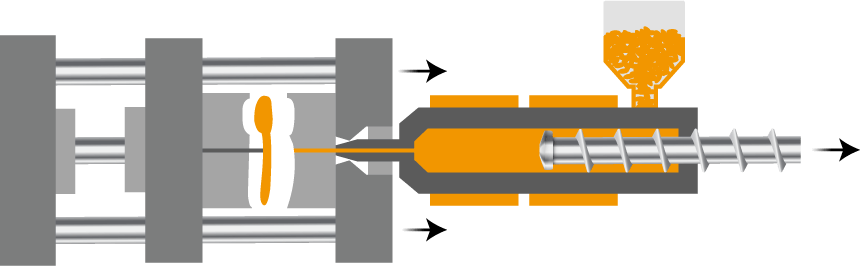

The plastic injection molding process is a continuous cycle, typically divided into five main stages:

- Plasticizing

Raw material is introduced into the barrel, where a screw mechanism blends and melts it. - Injection

The molten plastic is injected into the mold using the screw. - Packing

Pressure is applied to the mold cavity to prevent backflow and ensure the cavity is densely filled. - Cooling

Cooling channels within the mold lower the temperature of the molten plastic, solidifying it and providing adequate strength. - Ejection

Ejector pins in the mold push the solidified plastic part out, completing the demolding process.

Through the integration of these elements and process steps, plastic injection molding remains a cornerstone of modern manufacturing, supporting the creation of diverse and high-quality plastic products.

Plastic Injection Molding Process Diagram

Plastic Injection Molding Process Diagram